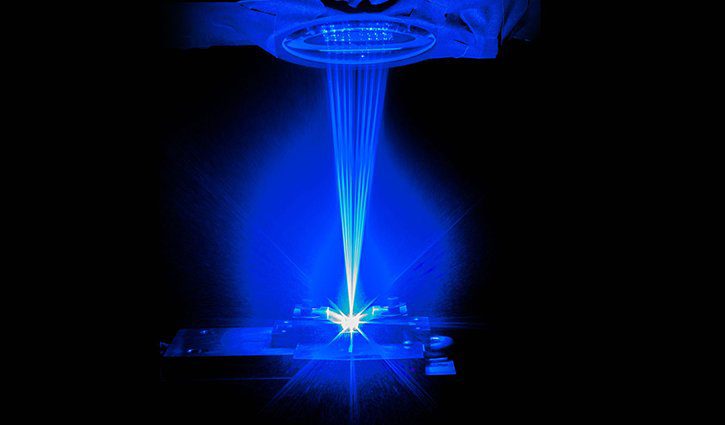

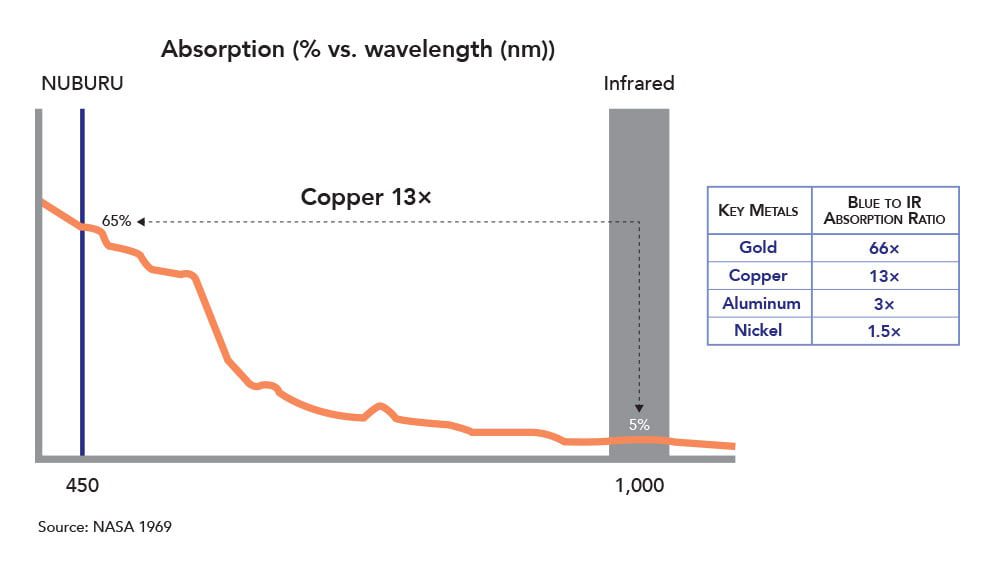

Physical Advantage of Industrial Blue Laser

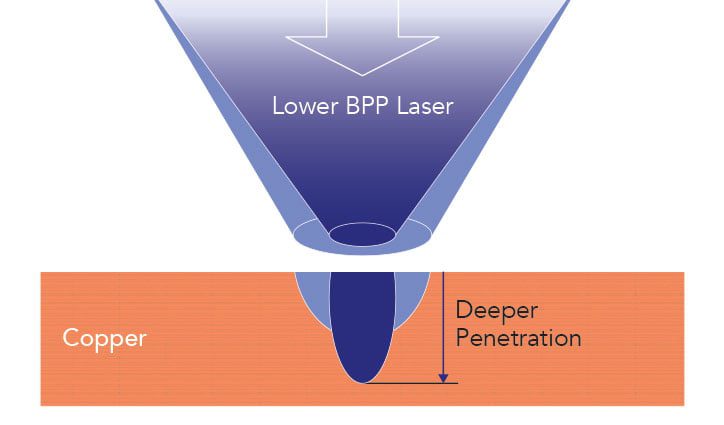

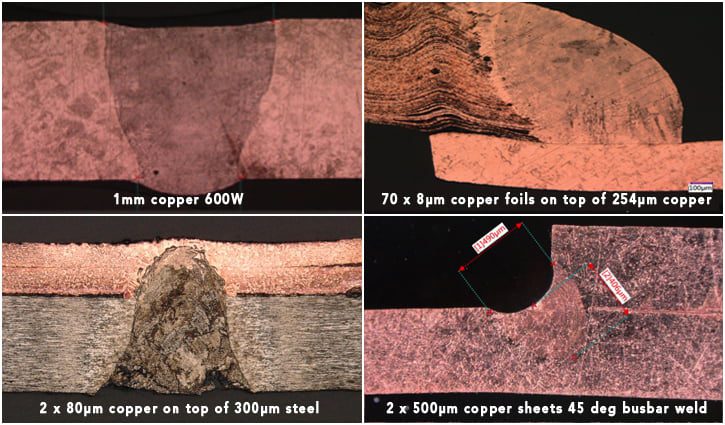

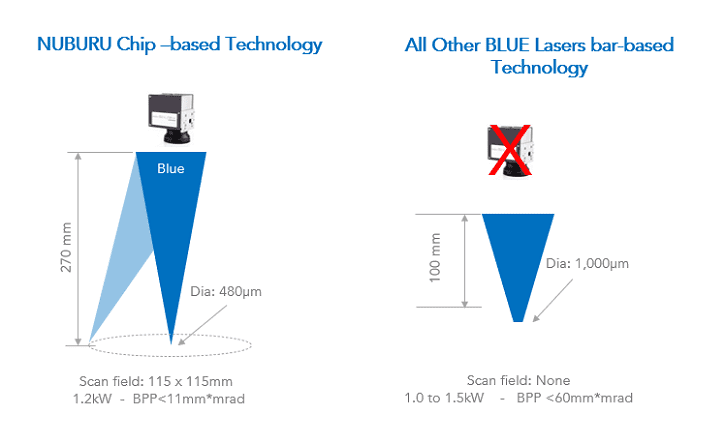

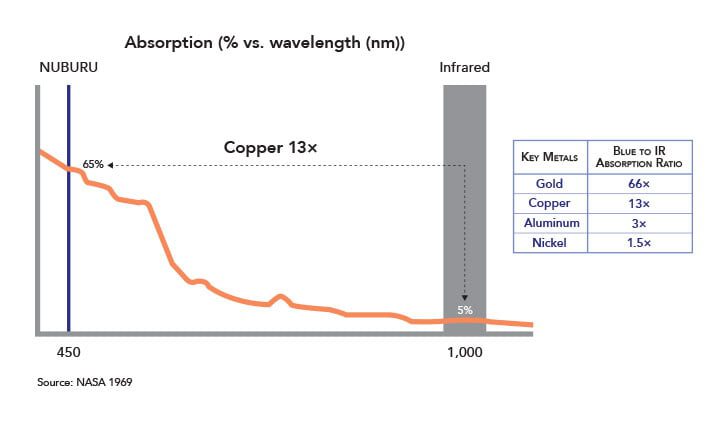

The blue laser welds copper faster and better than any alternative solution. This advantage springs from fundamental physics: copper absorbs blue light better than it absorbs infrared radiation or other colors of light. Aluminum, gold and other important industrial metals also absorb more blue than they do other wavelengths of light. That basic fundamental physical advantage leads to performance advantages for welding copper, welding aluminum, 3D printing, and other materials processing applications.